Trenchless technology has revolutionized sewer line repairs for plumbers, offering an efficient, modern alternative to traditional excavation methods. By using specialized equipment like high-pressure water jets and robots, plumbers can fix or replace pipes without surface access, minimizing site damage, reducing environmental impact, speeding up restoration times, and enabling remote work in challenging urban settings. This innovative approach provides numerous benefits over conventional methods, including reduced landscape disruption, faster repair times, lower costs, and minimal environmental harm. Plumbers leverage tools tailored to each job's unique challenges, such as Pipeline Inspection Gauge (PIG) pushing, Hydrojetting, and relining, ensuring efficient, non-invasive repairs that enhance customer satisfaction and are ideal for both commercial and residential projects.

“Discover revolutionary trenchless technology transforming sewer line repairs, a game-changer for plumbers. This innovative approach eliminates disruptive traditional digging methods. Learn how plumbers now repair or replace pipes with minimal excavation, saving time, money, and reducing project impact. From understanding the tech to choosing equipment and real-world case studies, this guide explores successful trenchless sewer repairs, empowering plumbers with efficient, effective solutions.”

- Understanding Trenchless Technology for Sewer Repairs

- Advantages of Using Trenchless Methods Over Traditional Digging

- Common Trenchless Techniques Employed by Plumbers

- How to Choose the Right Trenchless Equipment for Your Project

- Case Studies: Successful Trenchless Sewer Line Repairs

Understanding Trenchless Technology for Sewer Repairs

Trenchless technology has revolutionized the way plumbers approach sewer line repairs, offering a modern and efficient solution to traditional excavation methods. This innovative approach eliminates the need for extensive digging, reducing time, labor costs, and potential disruptions to surrounding infrastructure. By utilizing specialized equipment, such as high-pressure water jets and robotic machines, plumbers can now repair or replace sections of sewer pipes without accessing the line from the surface.

The benefits are numerous: it minimizes site damage, reduces environmental impact, and ensures faster restoration times. Trenchless technology allows plumbers to work remotely, targeting specific problem areas with precision. This method is particularly advantageous for challenging urban settings where navigating through bustling streets and underground complexes requires a delicate balance of skill and advanced equipment.

Advantages of Using Trenchless Methods Over Traditional Digging

Using trenchless technology offers several advantages over traditional digging methods for sewer line repairs, making it a preferred choice for many plumbers. One of the key benefits is minimal disruption to the surrounding area. Traditional digging requires large trenches, which can cause significant damage to landscapes, roads, and nearby structures. Trenchless methods, however, allow repairs to be carried out with small access points, leaving the surrounding environment largely intact. This is especially advantageous in urban areas where space is limited and disturbances can have a greater impact.

Additionally, trenchless technology often leads to faster completion times and reduced costs. By eliminating the need for extensive excavation, plumbers can efficiently repair or replace sewer lines without the time-consuming and labor-intensive process of traditional digging. This not only saves time but also reduces the overall cost of the project, making it a more economical option for both homeowners and commercial properties.

Common Trenchless Techniques Employed by Plumbers

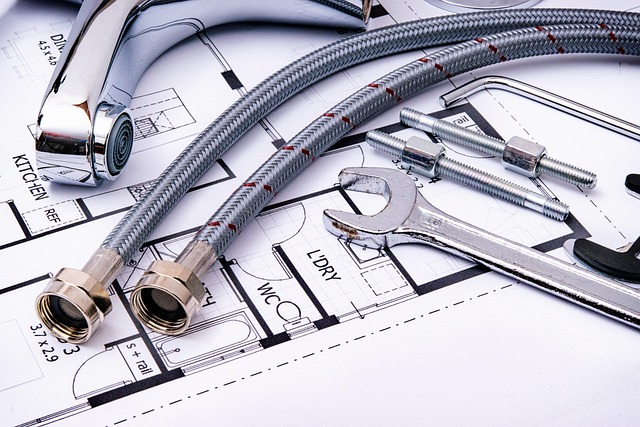

Plumbers often employ trenchless technology for sewer line repairs, offering a non-invasive approach that minimizes disruption to properties and surrounding landscapes. Among the common techniques are Pipeline Inspection Gauge (PIG) pushing, which involves inserting a specialized device into pipes to detect damage or blockages, and Hydrojetting, utilizing high-pressure water jets to clear obstructions without digging. Another popular method is relining, where a new pipe material is inserted into the existing line to reinforce and restore its structural integrity. These trenchless techniques not only speed up repair processes but also reduce costs and environmental impact, making them preferred choices for many plumbers.

How to Choose the Right Trenchless Equipment for Your Project

When it comes to trenchless sewer line repairs, selecting the right equipment is paramount for a successful and efficient project. Plumbers should consider the specific challenges presented by each job site. For instance, different types of pipes require tailored tools—high-pressure water jetters are ideal for cleaning and clearing obstructions in larger diameters, while smaller, more precise devices are suitable for intricate repairs in narrow corridors. Moreover, understanding the terrain is crucial; flexible equipment that can navigate tight bends and confined spaces is essential when working in urban areas with limited access.

The modern trenchless technology landscape offers a wide array of options, from advanced robotic systems to innovative inspection cameras. Plumbers should stay updated on industry trends, evaluating factors like equipment longevity, ease of use, and the potential for remote operation. Choosing the right gear not only streamlines the repair process but also minimizes disruptions to surrounding properties and roads, ensuring faster completion times and higher customer satisfaction.

Case Studies: Successful Trenchless Sewer Line Repairs

Trenchless technology has proven to be a game-changer in the field of plumbing, particularly for sewer line repairs. Numerous case studies showcase its effectiveness and efficiency. For instance, a major city faced a severe blockage in one of its main sewers, causing significant flooding and disruptions. A team of expert plumbers employed trenchless techniques, using advanced robots and high-pressure water jets to clear the blockage without digging. This method not only restored the sewer’s functionality but also minimized the closure of nearby streets, saving the municipality time and resources.

Another successful story involves a residential area plagued by frequent sewer leaks. A local plumber utilized trenchless technology to repair the lines without disturbing the landscape. By using fiber-optic cameras for inspection and precise cutting tools, they identified and fixed weaknesses in the pipes. This non-invasive approach left no visible scars on the grounds, ensuring the aesthetics of the neighborhood while providing a long-lasting solution. These real-world applications highlight how trenchless technology benefits both commercial and residential plumbing projects.

Trenchless technology has revolutionized sewer line repairs, offering a more efficient and less disruptive approach compared to traditional digging methods. By employing techniques like pipe relining, micro-excavation, and hydraulic excavation, plumbers can now restore damaged pipelines without the need for large trenches. This not only reduces construction site chaos but also saves time and money while minimizing environmental impact. With the right trenchless equipment and expertise, professionals can ensure long-lasting repairs, making it a preferred choice for modern plumbers. By embracing these innovative practices, the plumbing industry continues to evolve, providing effective solutions without disturbing our surroundings.