Plumbers play a vital role in maintaining water systems by identifying and replacing worn-out washers, valves, and seals. These components are essential for preventing leaks, ensuring pressure, and keeping appliances like washing machines running efficiently. A plumber's expertise involves inspecting, selecting the right parts (washers, cones, ball valves), replacing old pieces while cleaning corrosion, and offering tailored maintenance advice to avoid future damage. Regular upkeep guided by a plumber extends appliance lifespans and conserves water.

Looking to replace worn-out washers, valves, or seals? This comprehensive guide is your go-to resource. Learn how plumbers identify common issues like corroded parts or leaks, and master the step-by-step process of replacement. Discover the importance of choosing the right sizes and types for seamless installation. Plus, gain valuable tips to prevent premature wear and extend the lifespan of your appliances, all with expert plumber insights.

- Understanding Washer, Valve, and Seal Wear: Common Issues Plumbers Face

- The Role of a Plumber in Replacing Worn Parts: Step-by-Step Process

- Choosing the Right Replacement: Types and Sizes of Washers, Valves, and Seals

- Maintenance Tips: Preventing Early Wear and Extending Appliance Lifespan

Understanding Washer, Valve, and Seal Wear: Common Issues Plumbers Face

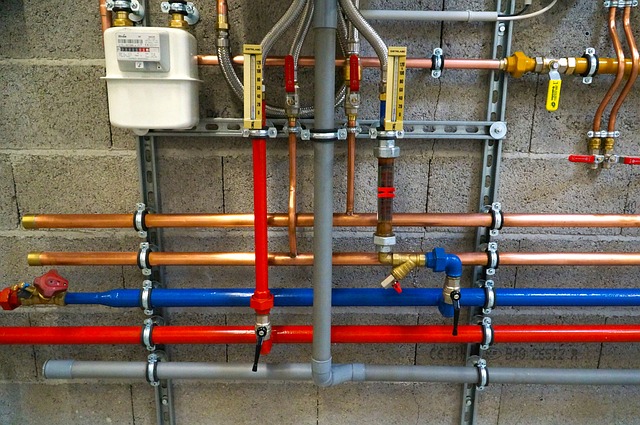

Plumbers often encounter worn-out or damaged washers, valves, and seals in their daily work. These components, though small, play a crucial role in maintaining water pressure and preventing leaks in plumbing systems. Washers, for instance, create a seal between two surfaces, while valves regulate the flow of water, and seals prevent the passage of contaminants or air into the system. Over time, these parts can become damaged due to wear and tear, corrosion, or exposure to harsh chemicals, leading to leaks, reduced water pressure, or even complete system failure.

Common issues include worn-out O-rings causing persistent leaks around valves, corroded seals allowing water to seep into joints, and frayed washers resulting in low water pressure. Plumbers need to be adept at identifying these problems and replacing them with new, compatible parts to ensure the plumbing system functions optimally. Regular maintenance and prompt replacement of worn components can help prevent more serious and costly repairs down the line.

The Role of a Plumber in Replacing Worn Parts: Step-by-Step Process

When it comes to replacing worn-out washers, valves, or seals, a plumber plays a pivotal role in ensuring your plumbing system operates smoothly and efficiently. The process involves several precise steps that require expertise and knowledge.

First, the plumber conducts a thorough inspection of the affected area, identifying the specific components in need of replacement. They then gather the necessary tools and parts, which may include new washers, valves, or seals tailored to the unique specifications of your plumbing system. Next, they carefully remove the old parts, taking note of their original positioning and any related components they might be connected to. This meticulous approach ensures proper alignment during installation, preventing future leaks or disruptions. Following removal, the plumber cleans the area, addressing any corrosion or debris that could interfere with the new parts’ functionality. Finally, they install the new washers, valves, or seals, ensuring a secure fit and proper sealing to maintain water pressure and prevent leaks.

Choosing the Right Replacement: Types and Sizes of Washers, Valves, and Seals

When it comes to replacing worn-out components like washers, valves, or seals, a plumber’s expertise is invaluable. The first step in any repair process is selecting the right replacement parts. Plumbers need to consider not only the physical dimensions but also the material composition and functionality of these components. Washers, for instance, come in various types, including flat, cone, and lock washers, each suited for specific applications and load-bearing requirements.

Valves, another crucial component, can be ball, butterfly, or gate valves, each designed for different flow control needs. Seals, on the other hand, must match the original specifications to ensure proper fitting and prevent leaks. Understanding these variations is key for plumbers to choose the most suitable replacements that will last, ensuring efficient water flow and preventing future damage.

Maintenance Tips: Preventing Early Wear and Extending Appliance Lifespan

Regular maintenance is key to keeping appliances in top shape and preventing early wear and tear. For washing machines, a plumber can offer valuable insights on maintaining their longevity. Start by checking and replacing any worn-out parts, such as washers, valves, or seals, promptly. These components are crucial for the machine’s efficient operation and water conservation.

Additionally, ensure proper drainage by clearing any clogs regularly. Using mild detergents and avoiding overloading the machine can also reduce strain on its parts. Remember, a plumber is your go-to expert for such tasks, providing guidance tailored to your specific washing machine model, ensuring it functions optimally and extends its lifespan.

When it comes to maintaining plumbing systems, a plumber’s expertise is invaluable. By understanding the common issues related to washer, valve, and seal wear, professionals can efficiently replace these parts, ensuring the smooth operation of appliances. With the right knowledge and tools, plumbers can offer effective solutions, prolonging the lifespan of various fixtures and equipment. Regular maintenance, including timely replacements, is key to preventing costly repairs and keeping plumbing systems in top condition.